Contact information

Theodore Lowe, Ap #867-859 Sit Rd, Azusa New York

We are available 24/ 7. Call Now. (888) 456-2790 (121) 255-53333 example@domain.comZinc Thermal

We design and develop web and mobile applications for our clients worldwide

Zinc Thermal Diffusion

Advanced Protection Through Zinc-Iron Alloy Coating

Zinc Thermal Diffusion is a cutting-edge surface treatment technology designed to deliver exceptional corrosion

resistance and durability. Through a high-temperature diffusion process, a zinc-iron alloy layer is formed directly on the

surface of the metal, creating a metallurgically bonded coating that will not flake, chip, or peel — even under extreme

conditions.

Unlike traditional electroplating or hot-dip galvanizing, Zinc Thermal Diffusion is a completely dry and eco-friendly

process. It eliminates the need for liquid baths or chemical waste, making it both environmentally sustainable and

operator safe. The result is a uniform, matte-grey finish with superior protection against corrosion, wear, and abrasion.

This technology is widely used in automotive, construction, defense, and industrial applications, particularly for

components that must withstand harsh outdoor or chemical environments.

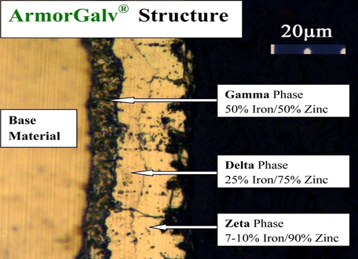

Renowned brands like ArmorGalv® by Distek have perfected this process, offering a proven alternative to traditional

coatings with longer service life, reduced maintenance, and outstanding performance.

Zinc Thermal Diffusion is the future of surface protection — durable, sustainable, and engineered for performance that

lasts.

Key Benefits:

- ● Exceptional corrosion resistance

- ● Uniform, chip-free zinc-iron alloy coating

- ● Environmentally friendly – no liquid effluents or toxic by-products

- ● Excellent wear and abrasion protection

- ● Ideal for complex geometries and threaded components

THERMAL ZINC DIFFUSION COATING (TZD)

TZD creates a zinc–iron alloy through a diffusion process, giving uniform, chip-proof, metallurgically bonded protection.

Key Benefits of TZD

- ● 3000+ hours corrosion resistance

- ● No peeling or cracking

- ● Uniform coating on threads and internal surfaces

- ● Eco-friendly, dry process

- ● High abrasion resistance

Property

Zinc Flake

PTFE

Zinc

Thermal

Spray

Alkaline Zinc

Alkaline Zinc Nickel

Hot-Dip Galvanizing (HDG)

Application

Method

Non-electrolytic

(Dip-Spin/Spray)

Spraying,

Coating

Thermal

SprayingVery Good to

Excellent

(Cathodic/Ba

rrier)

Electroplating

Electroplating

Immersion in Molten Zinc

Corrosion

Protection

Level

Excellent

(Cathodic/Barrie

r)

Good to

Excellent

(Barrier)

Very Good to

Excellent

(Cathodic/Ba

rrier)

Good

(Cathodic)

Superior

(Cathodic)

Excellent

(Cathodic/Barr

ier)

Thickness

Range

($\mu$m)

Thin (5-15)

Varies

greatlyGood to

Excellent

(Barrier)

Thick

(50-500)

Thin (5-20)

Thin (5-15)

Thick (45-200)

Unique

Selling

Proposition

(USP)

Absence of

Hydrogen

Embrittlement

Risk (Ideal for

high-strength

steel fasteners)

Extremely

Low

Coefficient

of Friction

(Non-Stick)

& Excellent

Chemical

Resistance

Ability to

Coat

Extremely

Large

Structures

On-Site

Exceptional

Throwing

Power and

Uniform

Coverage on

Complex

Parts

Highest

Corrosion

Resistance of

Electroplated

Coatings

(Often >1000

hrs salt spray)

Metallurgical

Bond & Most

Cost-Effectiv

e Long-Term

Solution for

Structural

Steel