Theodore Lowe, Ap #867-859 Sit Rd, Azusa New York

We are available 24/ 7. Call Now. (888) 456-2790 (121) 255-53333 example@domain.comProcess

We design and develop web and mobile applications for our clients worldwide

Process

Aum Dacro Coatings Process

Our Coating Process

At Aum Dacro Coatings , every component undergoes a meticulously controlled surface treatment process to ensure

the highest corrosion resistance, coating uniformity, and performance durability. Our process integrates advanced GEOMET® zinc flake coating technology , combining chemical precision,

mechanical pre-treatment, and robust quality control to deliver unmatched protection for fasteners and components.

1. Chemical Pre-Treatment – Preparing for Perfection

A well-prepared surface ensures the zinc flake coating forms a strong, lasting bond. Unlike conventional plating, zinc flake coatings eliminate hydrogen embrittlement, making them ideal for high-strength steel fasteners.

Our pre-treatment steps include:

Alkaline Cleaning:

Removes oils and dirt effectively.

Solvent Cleaning:

Targets stubborn organic residues.

Rinsing:

Eliminates chemical residues.

Optional Inhibitors:

Prevents flash rust formation.

Controlled Drying:

Ensures the surface is moisture-free before coating.

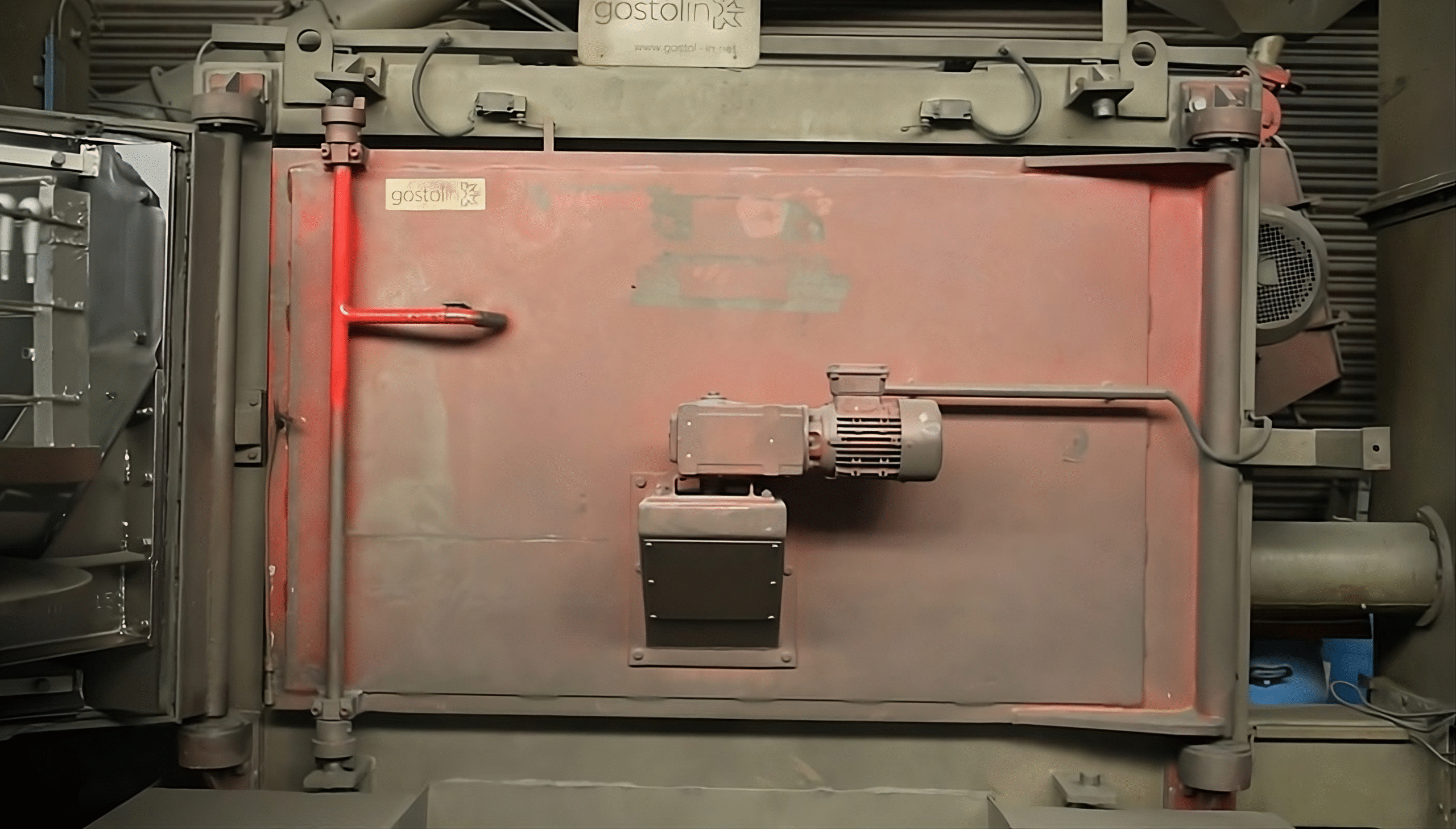

2. Mechanical Pre-Treatment – Surface Activation

Mechanical preparation enhances coating adhesion and surface roughness. Depending on component geometry, we employ different shot blasting techniques.

2.1 Table Type Shot Blasting

For flat or circular components (e.g., gears, discs).

Benefit: Uniform cleaning and easy handling.

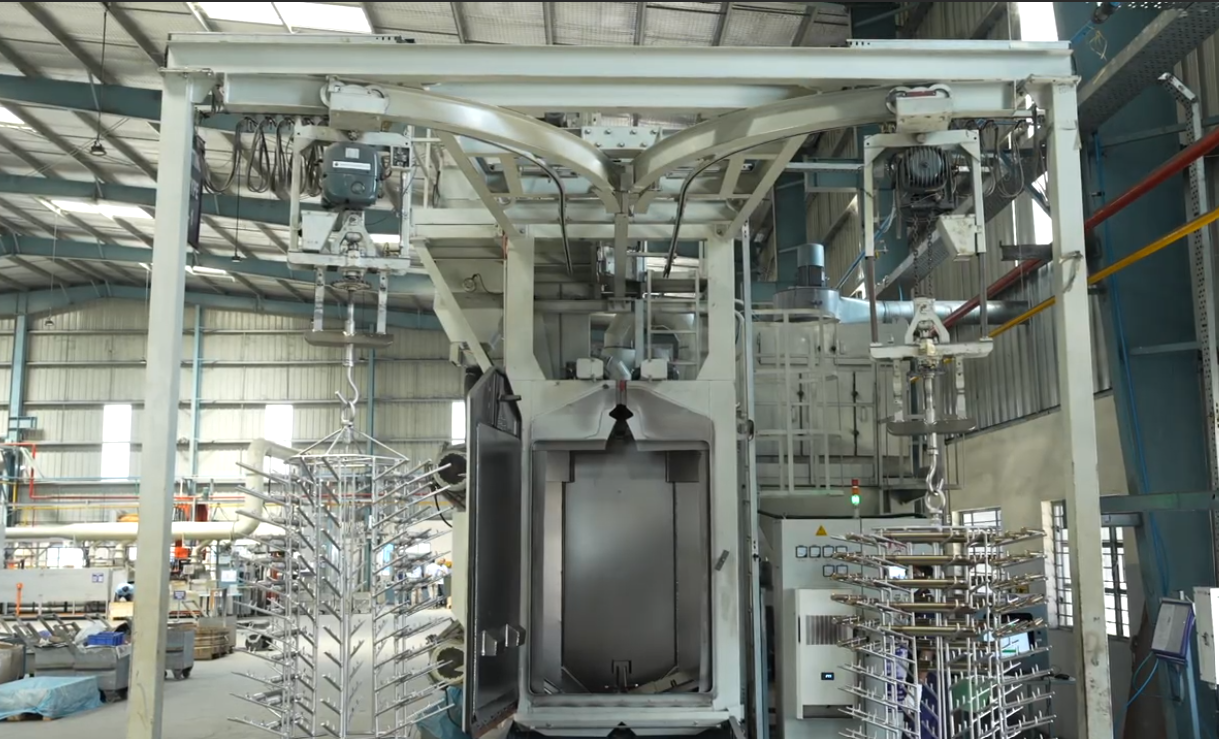

2.2 Hanger Type Shot Blasting

For large or complex components (e.g., frames, castings).

Benefit: 360° cleaning without part collision.

2.3 Tumble Type Shot Blasting

For bulk fasteners and small parts.

Benefit: High productivity with consistent results.

2.4 Sandblasting

For precision surface finishing or paint removal.

Benefit: Fine texture, improved adhesion, and surface durability.

Advantages of Proper Pre-Treatment:

Superior adhesion strength

Consistent coating finish

Reduced hydrogen embrittlement risk

Improved corrosion resistance

3. Coating Application – Precision in Every Layer

We apply GEOMET® zinc flake coatings using methods tailored to part size, geometry, and performance requirements.

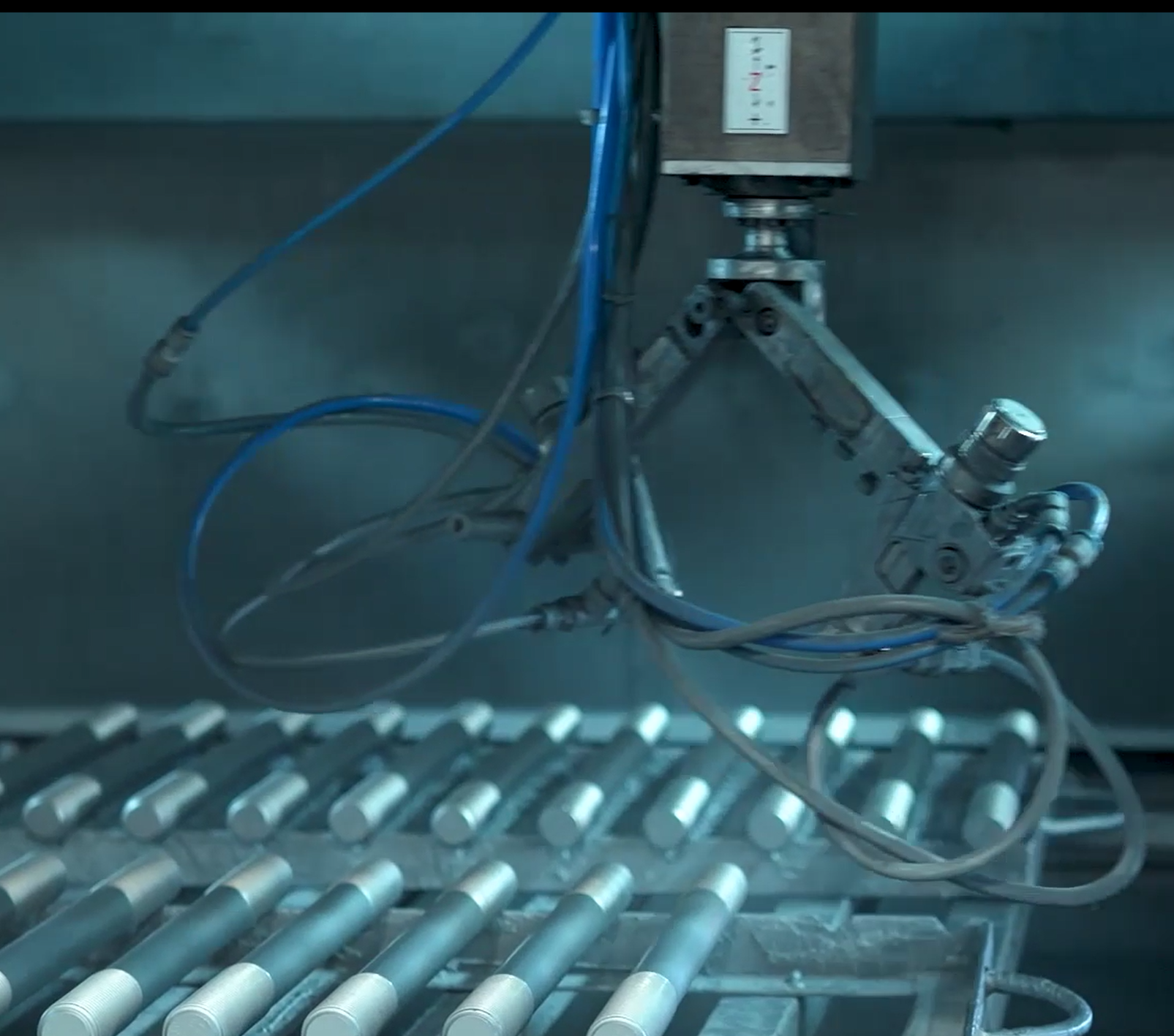

3.1 Spray Application

Used for large or complex parts.

Pros: Flexible, uniform coating.

Cons: Requires skilled operators.

3.2 Rack Dip-Spin

For medium-sized parts mounted on racks.

Pros: Consistent coating, suitable for threaded parts.

Cons: Limited for oversized components.

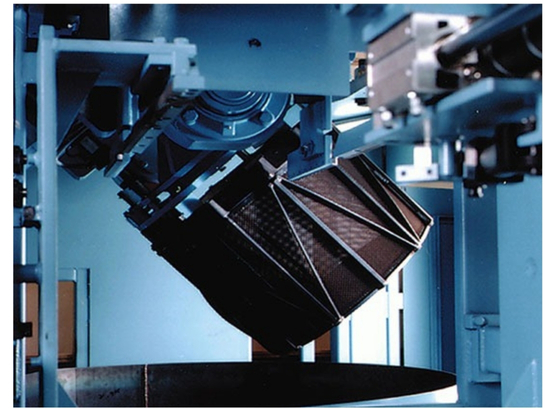

3.3 Bulk Dip-Spin

Ideal for small fasteners and mass production.

Pros: Material efficient, quick cycle.

Cons: May produce heavier coating in recesses.

3.4 Dip-Drain

Used for large or intricate components.

Pros: Suitable for thick coatings and large parts.

Cons: Longer cycle and less uniformity.

4. Curing – Strength Through Heat

After coating, parts undergo thermal curing to achieve maximum performance.

Typical Curing Range: 200°C – 320°C

Why It Matters:

Activates chemical bonding for a hard, stable layer

Improves mechanical strength and adhesion

Ensures corrosion resistance and thermal stability

The result is a uniform, tightly bonded coating layer that withstands harsh environments.

5. Final Inspection – Ensuring Perfection

Every batch is subjected to 100% visual and analytical inspection before dispatch.

Checks Include:

Coating uniformity and coverage

Thickness measurement (via XRF)

Adhesion, curing, and friction testing

Detection of pinholes, blisters, or uneven finish

Only fully compliant parts are approved, packed, and trace-tagged for quality assurance and easy lot tracking.

6. Testing & Quality Assurance

Our in-house testing facilities simulate real-world performance and validate coating integrity.

XRF Analyzer: Measures coating thickness and composition.

Optical Microscope: Detects micro-defects and flake distribution.

Salt Spray Test (SST): Evaluates corrosion resistance (e.g., 720–1000 hours without red rust).

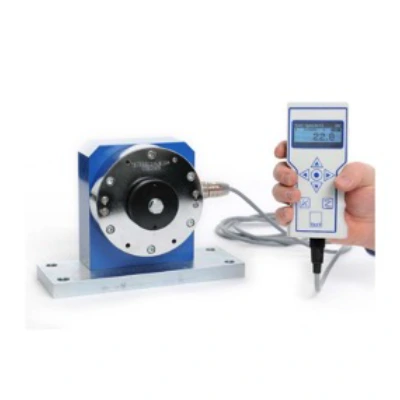

Coefficient of Friction (CoF) Test: Ensures reliable torque-tension

Lab Coater & Batch Oven: Used for R&D trials and curing validation before

These systems guarantee every coating batch meets automotive OEM and international standards such as ISO 10683, ASTM B117, and ISO 9227.