Theodore Lowe, Ap #867-859 Sit Rd, Azusa New York

We are available 24/ 7. Call Now. (888) 456-2790 (121) 255-53333 example@domain.comTop Coats

We design and develop web and mobile applications for our clients worldwide

Top Coats

Lubrication

Corrosion protection

Chemical resistance

Color tracing

No hydrogen embrittlement

Lubrication

Corrosion protection

Chemical resistance

Color tracing

No hydrogen embrittlement

Lubrication

Corrosion protection

Combined with our zinc flake basecoats, PLUS® VLh reacts and creates a barrier effect that improves both the

corrosion resistance of the system and the contact corrosion with aluminum and other materials.

Chemical resistance

Color tracing

UV tracing

No hydrogen embrittlement

Lubrication

Corrosion protection

Chemical resistance

Combined with our zinc flake basecoats, PLUS® ML Black reacts and creates a barrier effect that improves both the

corrosion resistance of the system and the contact corrosion with aluminum and other materials.

No hydrogen embrittlement

Lubrication

Corrosion protection

Temperature resistance

Chemical resistance

No hydrogen embrittlement

Lubrication

Corrosion protection

Resistance to industrial solvents and automotive fluids.

No hydrogen embrittlement

Lubrication

Corrosion protection

Chemical resistance

Color tracing

No hydrogen embrittlement

Lubrication

PLUS® 10 reacts and creates a barrier effect that improves both the corrosion resistance of the system and the contact

corrosion with aluminum and other materials.

Chemical resistance

No hydrogen embrittlement

Lubrication

0.14-0.20

Corrosion protection

Chemical resistance

Lubrication

Coloration

Corrosion protection

Chemical Resistance

Lubrication

Corrosion Protection

Chemical Resistance

Coloration

Scratch Resistance

Torquer Series

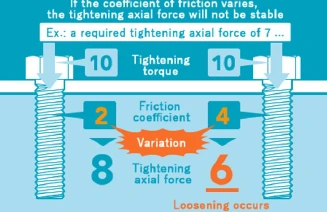

Preventing looseness / Cost reduction / Weight reduction The Torquer Series is effective in every situation

Increasing the size and number of bottles is not enough to prevent loosening.

Combined with our zinc flake basecoats, ECHOTE® WH700 reacts and creates a barrier effect that improves both the

corrosion resistance of the system and the galvanic corrosion protection with aluminum and different noble metals.

The most effective way to prevent loosening is to stabilize the coefficient of friction and exert an appropriate tightening

axial force.

01

Stable fastening axial force prevent looseness

02

A stable friction coefficient

03

Maximize the utilization of bolts without sacrificing performance

04

No more increasing the size in the number of bolts

Zinc Flake

PTFE

Zinc

Thermal

Spray

Alkaline Zinc

Alkaline Zinc Nickel

Hot-Dip Galvanizing (HDG)

Electroplating

Thickness

Range

($\mu$m)

Extremely

Low

Coefficient

of Friction

(Non-Stick)

& Excellent

Chemical

Resistance